Module Inspection

Raise the efficiency of your production

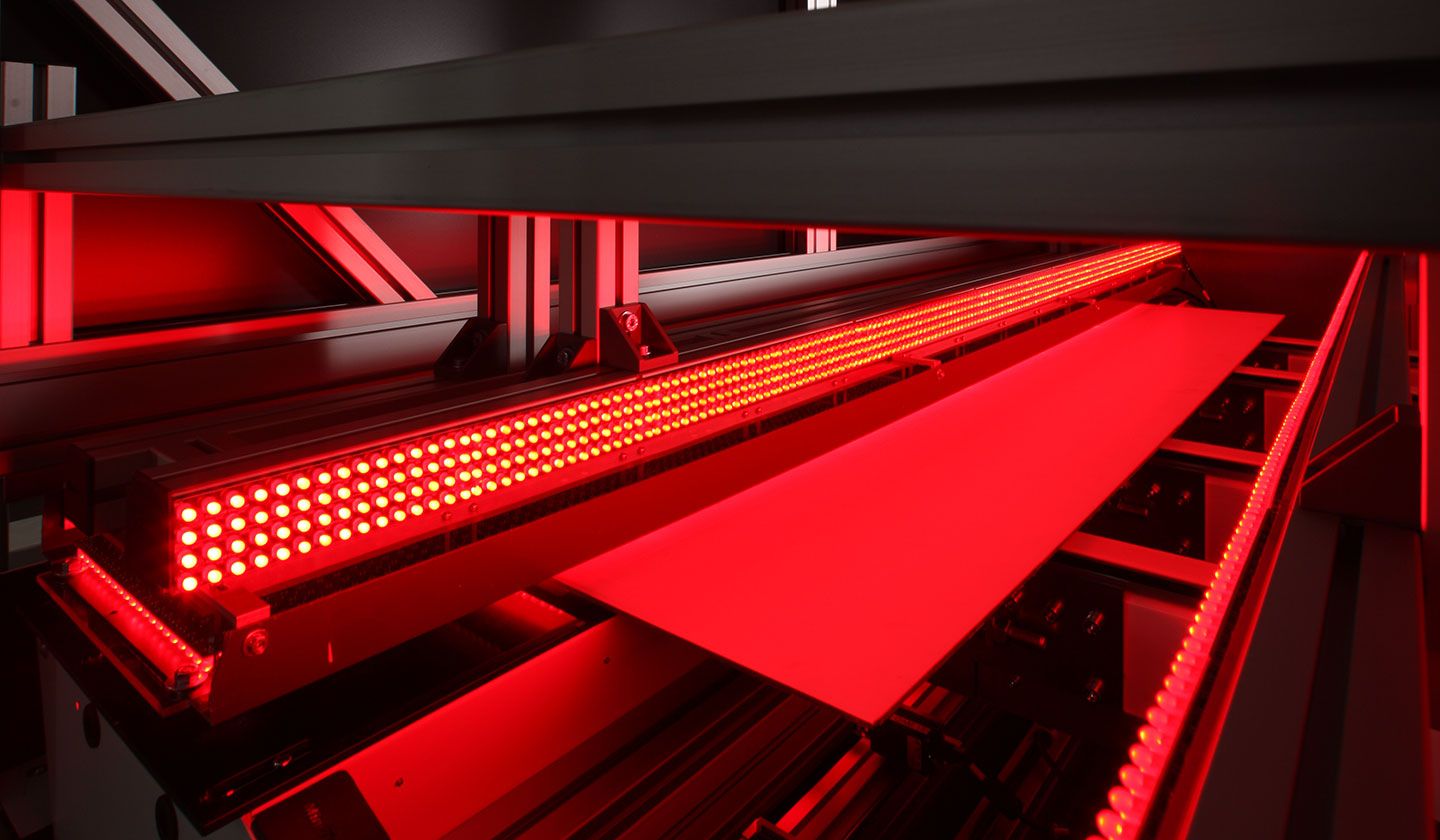

In manufacturing crystalline solar modules, single solar cells are soldered to strings and then laminated to high value modules. After the irreversible lamination process it is not possible to correct faults, so only perfect layups/matrices should be processed. Our VELA inspection systems offer a fully automated solution prior to and after the lamination process step.

String inspection

The VELA string inspection system is located directly after the soldering station in the stringer. Its size is relatively small and it can be adapted to different stringer machines.

- Measurement of cell-to-cell distances

- Measurement of ribbon alignment and orientation

- Recognition of folded or damaged ribbons

- Detection of breakage during soldering

Layup/Matrix inspection tasks

The VELA layup/matrix inspection system is located upstream of the lamination process to separate out faulty parts for manual repair, which conserves the faulty layups/matrices. Layups/matrices with sizes up to 1.4 × 2.0 m² are handled within the typical production cycle times. The front and back sides are inspected simultaneously.

- Measurement of distances between the cells and the frame

- Measurement of string alignment and orientation

- Detection of cracks, holes or chippings on the cells

- Recognition of misaligned ribbons

- Detection of impurities, e.g. inclusions (especially conductive contaminations that can cause shunts), between and on cells

- Control of colour homogeneity

- Reading labels, e.g. barcodes

Laminate inspection tasks

The VELA laminate inspection system is designed to provide a final inspection of the completed laminate and is thus located after the laminator. Laminates with sizes up to 1.4 × 2.0 m² are handled within the typical production cycle times. The front and back sides are inspected simultaneously.

- Measurement of distances between the cells and the frame

- Detection of cracks, holes or chippings on the cells

- Recognition of misaligned ribbons

- Detection of impurities such as inclusions

- Control of colour homogeneity

- Print inspection of the cells

- Detection of damages and bubbles on both sides

- Recognition of non-laminated areas

- Reading labels, e.g. barcodes

Your contact for module inspection

Andreas Eckl

+49 9131 61082-220

andreas.eckl@intego.de