Tube Inspection

Raise the efficiency of your production

In manufacturing metal and polymer tubes, the early detection and prevention of faults is essential for quality and safety reasons. Our inspection systems are designed for a fully automated 100 % inspection rate in rough industrial environments. We offer 3D measurement systems for inner and outer tube surfaces with fast laser triangulation.

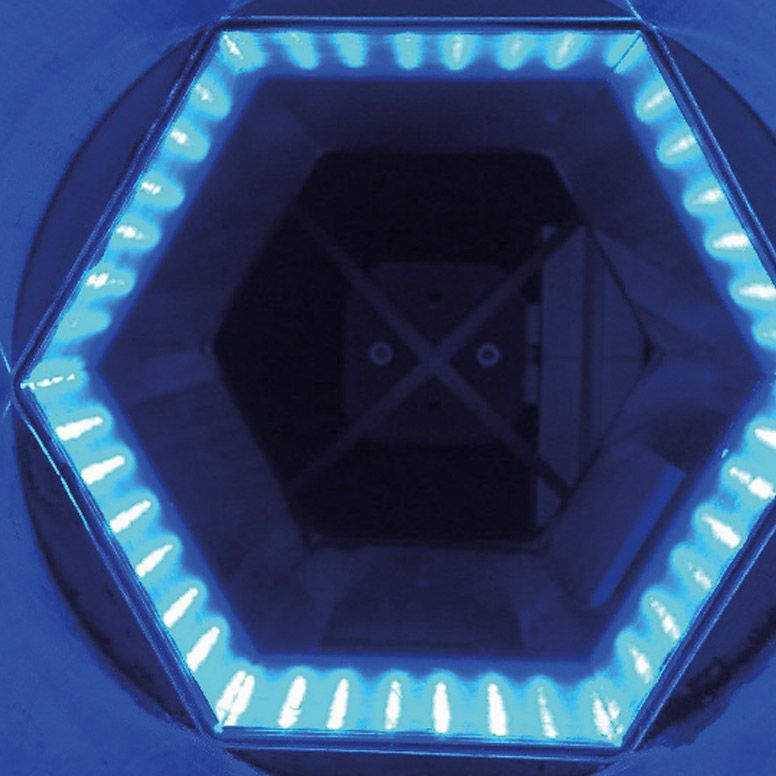

Key facts for 3D inner tube inspection

Our inner tube inspection system has been developed to inspect the entire interior surface of short tubes. The inspection includes detection and measurement of the smallest grooves and bumps, which cannot be seen by standard eddy current or ultrasound equipment. A new 3D measurement technique allows the detection of surface damages with an unsurpassed accuracy. Grooves as small as 50 μm can be reliably detected.

- Tube length up to 350 mm

- Inner tube diameter 16–35 mm

- Minimal groove depth 50 μm

- Measurement time approx. 5–12 s

- Other tube designs on request

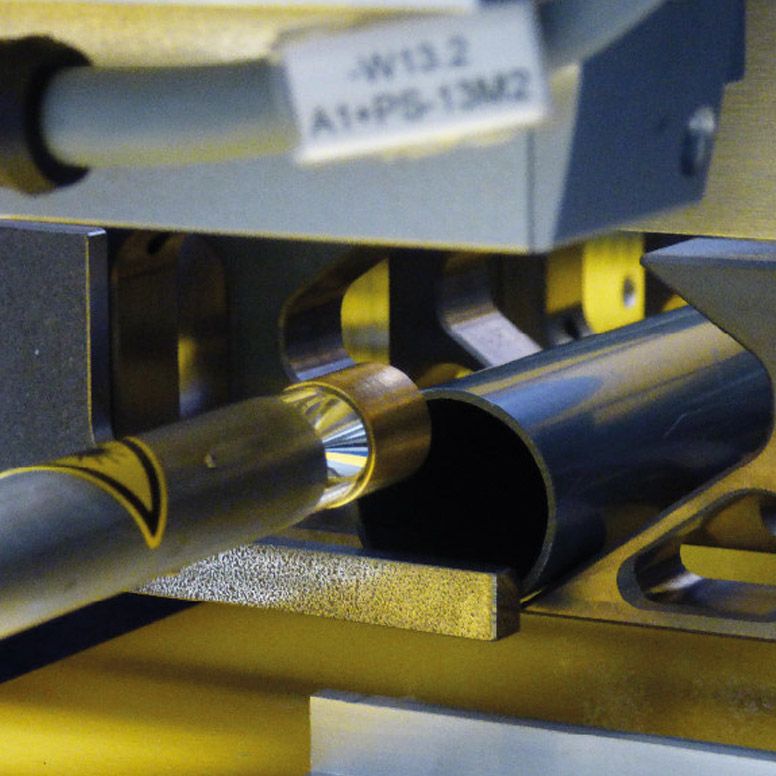

Key facts for 3D outer tube inspection

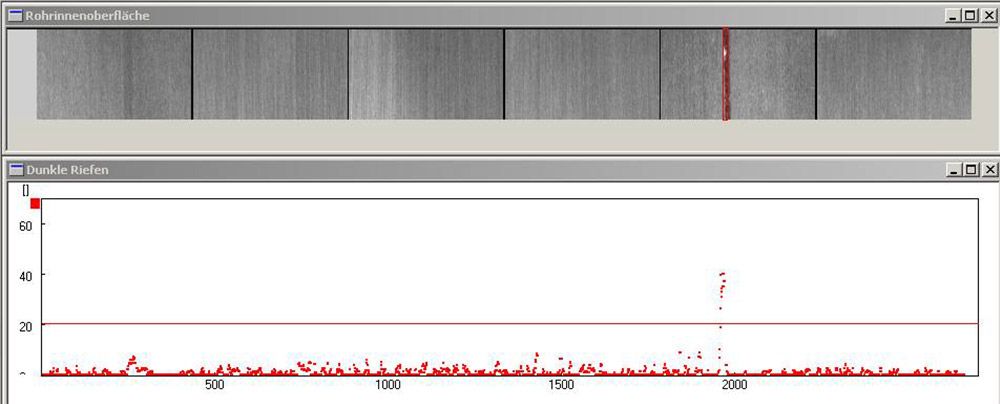

By using a multi camera 3D triangulation setup, the entire exterior surface of the tube is inspected at a throughput speed of up to 2 m/s. Camera resolutions can be configured specifically to the area of application. Depending on the throughput speed, a resolution in the feed direction of at least 0.7 mm is possible. The radial and lateral resolutions are around 10 μm and 100 μm, respectively. By merging information from the 3D measurements and an additional 2D vision system, the smallest surface defects such as score marks, scratches, mechanical damages, overlaps, holes, form deviation and much more can be reliably detected.

- Tube length any

- Outer tube diameter 20–80 mm

- Minimal groove depth 50 μm

- Throughput speed 2 m/s

- Other tube designs on request

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for tube inspection

Dr. Steffen Oppel

+49 9131 61082-230

steffen.oppel@intego.de