Electronic Inspection

High-performance and innovative inspection systems are essential to meet the quality standards. We manufacture inspection systems for the production of power electronics, circuit boards, batteries and battery components as well as printed and flexible electronics (displays). Measurements with high spatial resolution and fast cycle time are a key competence of Intego. Our inspection systems have a coordinated ratio of automation, image acquisition and data analysis, electrical tests are also possible.

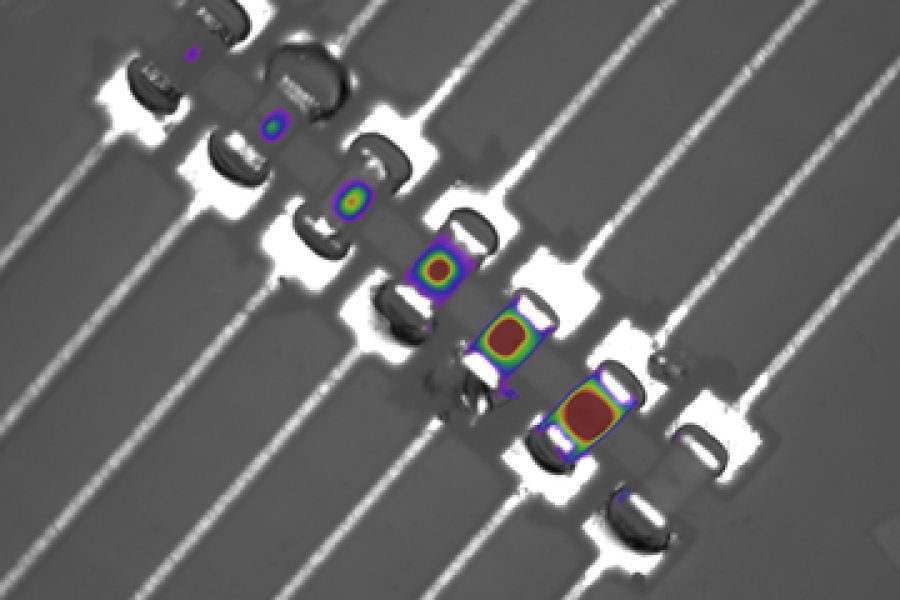

Intego's know-how enables the identification of challenging defects that may also be located below the surface, e. g. by means of lock-in thermography, for example, which visualizes the signal of the IR radiation intensity of electronics.

Intego is a specialist for high-resolution testing of small structures for electronics (components, lithography, SMD resistors). The possible inspection targets as well as the available measuring units can be found under special topics.