Plastic Inspection

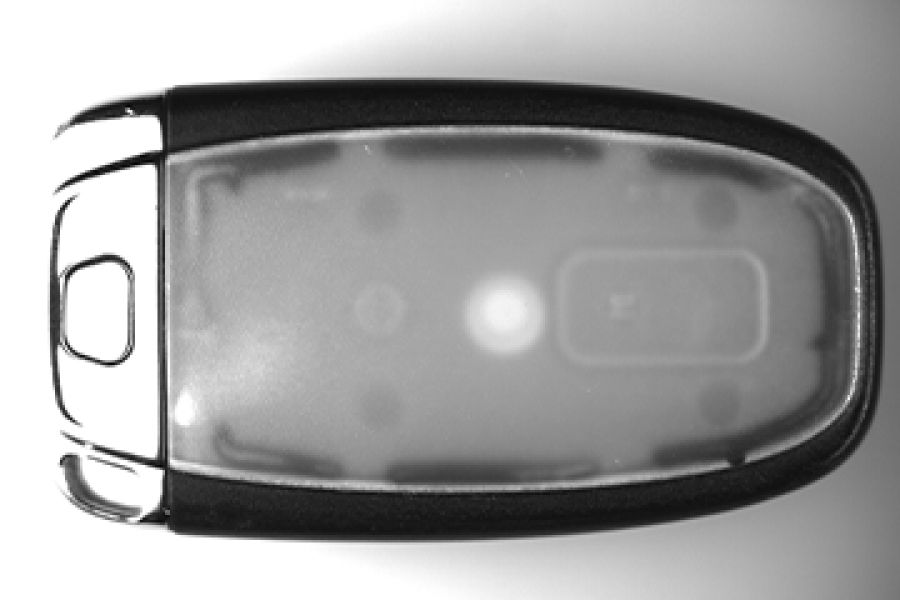

We help you to automatically inspect your products for optical quality faults.

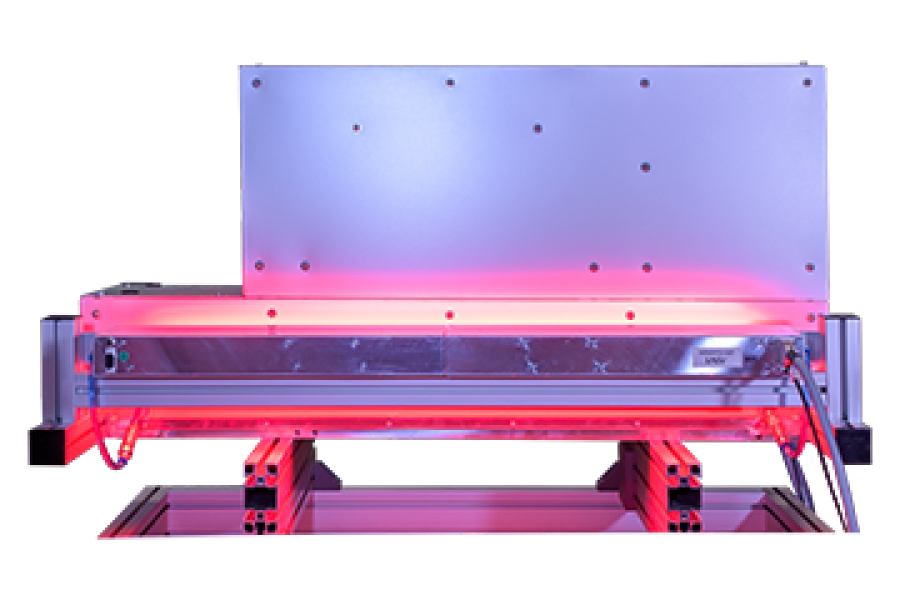

With the plastic inspection systems, you achieve a 100% inspection rate for your manufactured products, thus ensuring high product quality and lower manufacturing costs. Reacting quickly to faults also reduces the number of rejects. It is possible to provide reliable and objective fault detection that is broken down by the fault types. Because the inspection results are calculated and displayed immediately, they can be used for process control and optimization. Furthermore, a subsequent statistical evaluation of the production process is provided. Newly established in our portfolio are the EVOinspect systems for transmission measurement and foil inspection.

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate.